Special iron soldering aluminum foil for electric ceramic furnace

At present, the kitchen electrical appliances commonly used by people are mainly electromagnetic furnace and traditional light wave furnace; Induction cooker can not use small fire for continuous heating, and will produce electromagnetic waves harmful to human body, which is harmful to human body and health. The heat of traditional light wave furnace can not be heated quickly. You can't stir fry, and it's a waste of energy. In order to overcome the shortcomings of the existing kitchen utensils, a new kitchen utensil product - high-grade electric ceramic stove has been developed at home and abroad. As an enterprise specializing in the development of electrothermal alloy, our company designs this kind of electric ceramic furnace. A new type of Fe Cr Al foil is developed, which is specially used to make the heating elements of electric ceramic furnace.

Keys:

Electric heating alloy, constantan

Classification:

Hotline:

At present, the kitchen electrical appliances commonly used by people are mainly electromagnetic furnace and traditional light wave furnace; Induction cooker can not use small fire for continuous heating, and will produce electromagnetic waves harmful to human body, which is harmful to human body and health. The heat of traditional light wave furnace can not be heated quickly. You can't stir fry, and it's a waste of energy.

In order to overcome the shortcomings of the existing kitchen utensils, a new kitchen utensil product - high-grade electric ceramic stove has been developed at home and abroad. As an enterprise specializing in the development of electrothermal alloy, our company designs this kind of electric ceramic furnace. A new type of Fe Cr Al foil is developed, which is specially used to make the heating elements of electric ceramic furnace.

Specifications:

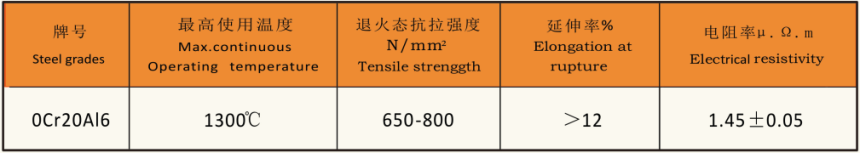

Thickness: 0.04-0.1mm, allowable deviation ± 4%

Width: 5-120mm, allowable deviation ± 0.05mm

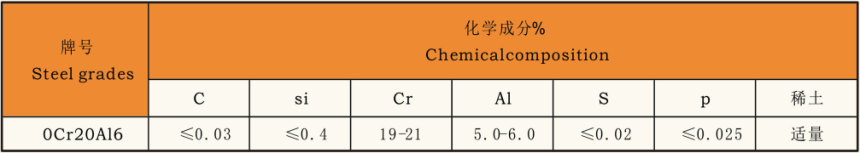

The alloy has good plasticity and good cold working formability. The electronic fluctuation is small, the fluctuation value of meter resistance is ≤ 4%, and the heating is uniform. Due to the addition of special trace elements, it is beneficial to form a dense oxide film firmly bonded with the matrix during heating, because it has strong high-temperature oxidation resistance. The existence of these trace elements can greatly improve the creep resistance of the alloy at high temperature. The material will not deform after long-term use at high temperature.

Previous

Previous

Thin Wide Strip for glass top hot plates

Message Consultation

If you have any suggestions, please leave us a message and we will reply to you within 1 working day after receiving the message.