Manufacturing capacity

Manufacturing Capacity

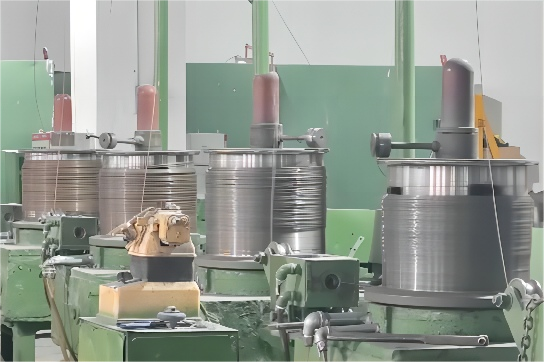

At present, the company has a large number of advanced production equipment and testing equipment such as medium frequency furnace, electroslag furnace, continuous drawing machine, well furnace, medium wire water tank machine, oil drawing machine, hydrogen furnace, automatic test packaging machine direct reading spectrometer, resistance uniformity analyzer, ultrasonic grinding machine, tensile testing machine, salt spray test box, life test bench and resistance testing instruments. After smelting, electroslag, well annealing, black wire cold drawing, hydrogen withdrawal, medium wire cold drawing, oil drawing, flattening, hydrogen withdrawal, finished product testing and packaging, the final product is formed.

STEP1

Smelting

STEP2

Casting

STEP3

Refining

STEP4

Steel rolling

STEP5

Thick wire cold drawing

STEP6

Well furnace annealing

STEP7

Continuous pulling

STEP8

Thick silk hydrogen retreat

STEP9

Cold drawn medium wire

STEP10

Oil pull

STEP11

Flat wire

STEP12

Hydrogen dehydrogenation

STEP13

Finished product inspection